Business Outline

We specialize in injection moulding, painting, and assembling interior/exterior parts of the automobiles and plastic parts of the motorcycle/home appliances. We also receive many requests for moulding of painted products and paintless materials. We aim to provide products and services with satisfying quality utilizing hand painting line, electrostatic painting line, automatic robot painting line to adapt all varieties of product specification. We also respond to diverse requests such as (moulding only), (moulding and assembly), (moulding and panting), (moulding, painting and assembly), (painting only), (painting and assembly) upon our customers requests.

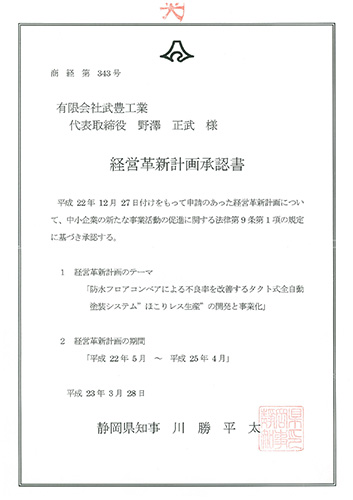

Management Innovation

In March 2011,we have obtained a recognition of the business management innovation with our theme “development and commercialization of a dust free production”, a TACT style fully automatic painting system to improve the defects of waterproof floor conveyors. We completed an automatic pre-processing facility which is not possible to do with floor conveyor to provide a stabilized pre-processing and it cleans accretions such as dust and thus reduce the defect rates.

Process

Moulding Process

| Injection Moulding | 230 tons (Electric Motor) x 1 |

|---|

Painting and Assembly Process

| Masking | Masking tapes and Jig |

|---|---|

| Preprocessing | Solvent cleaning(IPA) |

| Painting | “1. Overhead line 1) Hand painting line (4C1B, drying temperature up to 90℃ for 40 min) Product dimension up to 750 x 750 x 1200 2.Turntable style 3.Floor conveyor line |

| Appearance Inspection | We inspect based on the product specification |

| Assembly and fabrication | Sticker, rubber mold application, emblem application, clipping assembly, screw driver assembly |

| Packing | We pack based on the products packing instructions |

| Shipping | We ship to any designated addresses |